Kunye nophuhliso oluqhubekayo lwesayensi nethekhinoloji, iinjineli zoyilo lwezixhobo zombane kufuneka ziqhubeke nokulandela emanyathelweni enzululwazi kunye nethekhinoloji ekrelekrele, ukukhetha izixhobo ze-elektroniki ezifanelekileyo kwimpahla, ukwenzela ukuba iimpahla zihambelane ngakumbi neemfuno amaxesha. Apho iI-MOSFET ngamacandelo asisiseko okwenziwa kwesixhobo sombane, kwaye ke ngoko ufuna ukukhetha i-MOSFET efanelekileyo kubaluleke kakhulu ukubamba iimpawu zayo kunye neentlobo ngeentlobo zezalathi.

Kwindlela yokukhetha imodeli ye-MOSFET, ukusuka kwisakhiwo sefom (uhlobo lwe-N okanye uhlobo lwe-P), amandla ombane osebenzayo, ukusebenza kokutshintsha kwamandla, izinto zokupakisha kunye neempawu zayo ezaziwayo, ukumelana nokusetyenziswa kweemveliso ezahlukeneyo, iimfuno zilandelwa ngokwahlukeneyo, siya kuchaza oku kulandelayoUkupakishwa kweMOSFET.

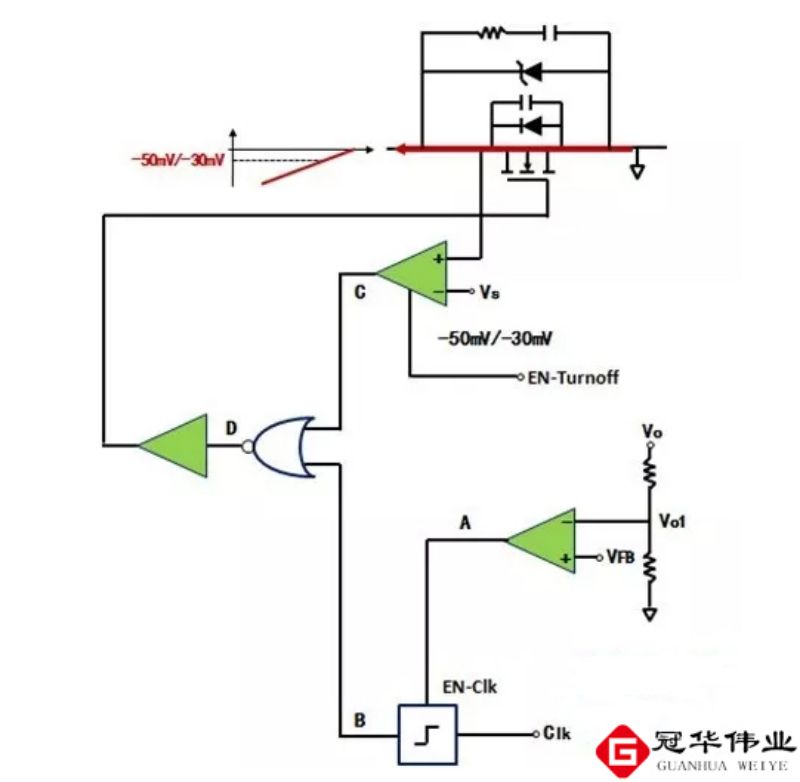

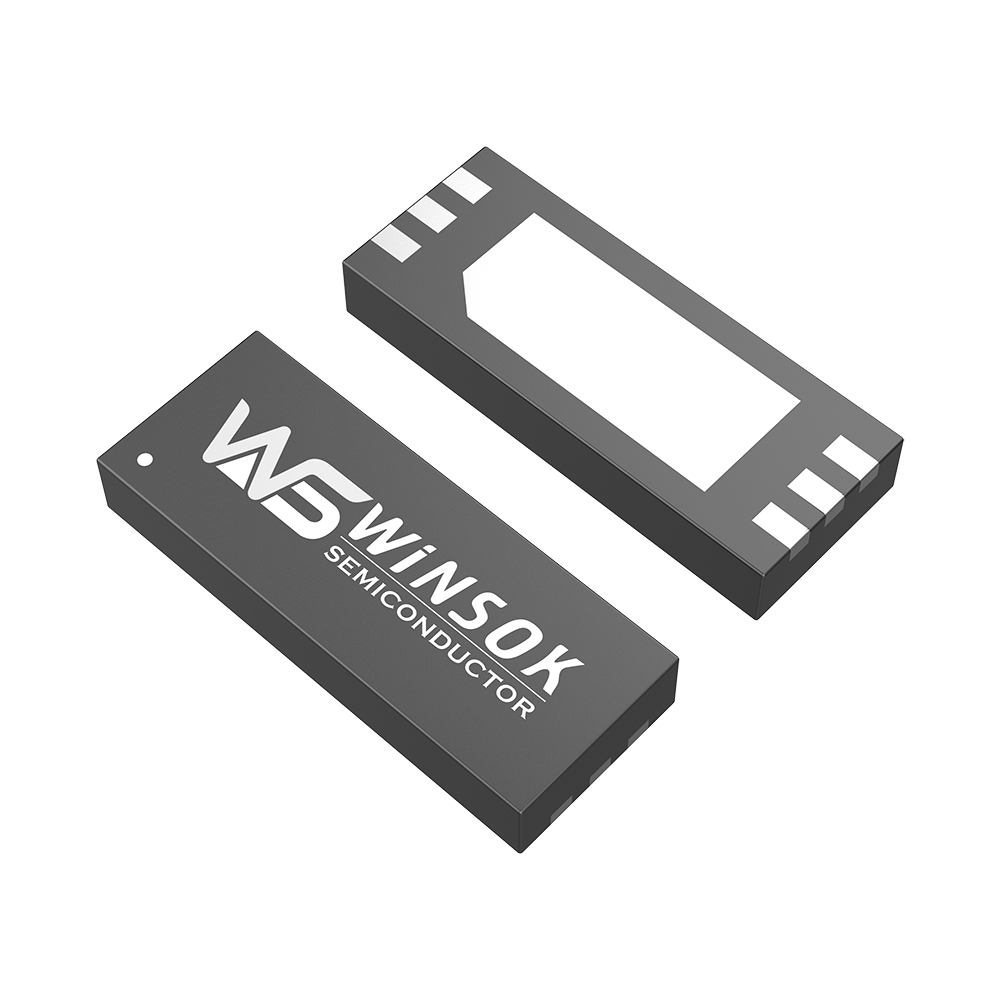

Emva kweI-MOSFET I-chip yenziwe, kufuneka ifakwe ngaphambi kokuba isetyenziswe. Ukuyibeka ngokuthe ngqo, ukupakishwa kukongeza i-chip ye-MOSFET, eli tyala linendawo yokuxhasa, ukugcinwa, isiphumo sokupholisa, kwaye kwangaxeshanye inika ukhuselo lwe-chip grounding kunye nokhuseleko, lula kumacandelo e-MOSFET kunye namanye amacandelo ukwenza. isekethe yonikezelo lwamandla eneenkcukacha.

Iphakheji ye-MOSFET yamandla emveliso ifakiwe kunye novavanyo lokunyuka komphezulu amacandelo amabini. Ufakelo sisikhonkwane se-MOSFET ngokusebenzisa i-PCB efakela imingxuma i-soldering ye-solder kwi-PCB. Ukunyuka komphezulu zizikhonkwane ze-MOSFET kunye nendlela yokukhutshwa kobushushu yokuthengisa kumphezulu womaleko we-PCB welding.

Izixhobo ze-Chip ekrwada, itekhnoloji yokucubungula yinto ephambili yokusebenza kunye nomgangatho we-MOSFETs, ukubaluleka kokuphucula ukusebenza kwabenzi bokwenza i-MOSFETs kuya kuba kulwakhiwo oluphambili lwetshiphu, ukuxinana okuhambelanayo kunye nenqanaba letekhnoloji yokuqhubela phambili ukwenza uphuculo. , kwaye olu phuculo lobugcisa luya kufakwa kwixabiso eliphezulu kakhulu. Itekhnoloji yokupakisha iya kuba nefuthe elithe ngqo kwintsebenzo eyahlukeneyo kunye nomgangatho we-chip, ubuso be-chip efanayo kufuneka bupakishwe ngendlela eyahlukileyo, oko kunokuphucula ukusebenza kwetshiphu.